In the professional path of an entrepreneur, several obstacles may arise, and sometimes they can be pretty imposing. These will test our ability to overcome adversity, they will develop our resilience and really put our team to the test. They are make-or-break situations. And as everything happens at the same time in life, when you do encounter this great obstacle, if you happen to be in the process of renovating your facilities and you happen to be pregnant, it does not make things easier, let me tell you! Here is an experience that sums up perfectly the fact that the worst scenarios can still have a happy ending…

The mystery of the rancid smelling granola

This story was worthy of an investigation by Sherlock Holmes… In 2017, a bad ingredient supply almost caused us to go bankrupt.

At first, we began to receive some complaints from our loyal customers, who told us that the taste of our products had changed, and not for the better. It was a first for us, so we wanted to find the cause as quickly as possible and make sure other products did not have the same problem. Our customers complained of a rancid taste while the product was still very fresh, just out of our production workshop only a few weeks earlier. This was the same kind of remark we had received in the past for a product close to its expiration date.

We instantly mobilized the team to find the answer: we opened bags, made batch follow-ups, tastings… In short, our main goal was to target and identify the problem, and fast (was it just one production, one product, several flavours, several productions???).

We needed to remain calm and be logical. We analyzed the ingredients used in the product for which we had received the complaints, and isolated those which more likely to become rancid and affect the taste: grains, oil, flour… We contacted our suppliers to know the dates of manufacture of these raw ingredients. At the same time, we got an external laboratory to help us. Several weeks and several new complaints later, after many internal discussions and communications with the laboratory, we finally thought we had targeted the problem: According to the samples provided, they were able to determine that the ingredient responsible for all this chaos was most certainly the oil. How was it possible, knowing that we have always used the same oil without changing our supplier recently? We had never had a problem with the oil in the past, and it seemed at that moment to have contaminated the whole product with an unpleasant smell of paint.

In order to continue our investigation, we compared the data from the laboratory with the oil specification sheets that the supplier finally shared with us following several urgent requests that we made. At that moment, we realized the oil was not the one we usually order, that met our usual requirements. How long had we been using the wrong oil? Were we still using the same oil? STOP, we needed to halt the production!

The outcome

The Quebec supplier with whom we had been working had changed its supply without informing us. Moreover, he sold us a low-quality oil at a the same high price, lying to us about the product we bought from him. We were unable to know that this was not the same oil we had received on all previous orders because this information was not on the product packaging; indeed, no indication was provided in this regard. It was time to get the lawyers involved.

We had to block the production and look for another supplier. It was confirmed that all the products that had been manufactured in the past 3 months were contaminated by this non-compliant oil. It had the effect of aggressively shortening the shelf-life of our products and giving them a bad odor and an unpleasant taste — even more unpleasant than products made with the right oil, but past their expiry date. Just to complicate everything, the other potential suppliers who could help us out were also selling the same low-quality oil (most likely sourced from the same supplier).

It was time to make a tough decision, and this was happening while I was 6 months pregnant: Recall thousands of products to destroy or leave them on sale at the risk of ruining the reputation of our products. I had contacted my insurance broker who told me that the loss would not be covered. STRESS… lots of stress. Unsatisfied with her answer, I took the initiative to read my insurance policy in order to understand why we were not covered for this type of situation. Obviously, after paying insurance for years, you want to be able to benefit from it the day you need it… Finally, I found the clause to that effect, even if it was a little ambiguous. I contacted my broker once again who put me in direct communication with the insurer in order to discuss further. Anxious, I told the claims adjuster the circumstances surrounding our problem. He told me he was going to analyze the case and call me back in the next hour. I joined my employees in a team lunch as if nothing had happened, while I knew that the future of the company was at stake. At the end of the lunch, I received the call from the insurer, I went quickly to my office, and closed the door: he confirmed that the damage was covered and informed me of the covered maximums and the eligible costs.

I had already made the decision to proceed with the recall in different sales locations, but at that moment I gave the final “GO” for a large-scale recall. It was also necessary to prepare a reassuring note for the customers. Indeed, if Health Canada felt our products could still be marketed considering they were not dangerous (they just had a bad taste), it was necessary to restore the trust of our loyal customers as well as our business partners.

Fortunately, in this nightmare, I was able to count on the precious help and patience of our distributors. Removing products is one thing, but it was also necessary to replace them. It was important to produce enough in order to fill the gap that was left, so the stress was at its peak. In addition, we had dozens of pallets of products quarantined in our warehouse, all contaminated with the bad oil that we could not sell and that cluttered our space. It took several weeks to replace all the products and we were anxiously waiting for merchandise credit reports to see if we would exceed the maximums covered by the insurers. I would like to point out that insurers and lawyers were valuable allies in this process, and, without them, I am convinced that we might not have survived financially.

Limit the damage

Five months later, we finally saw the light at the end of the tunnel. In the meantime, we dealt with more than 50 complaints and had to explain to customers, in a transparent way, what had happened with our production. Normally, the majority of customers will not take the time to complain, they simply stop buying. We also lost important listings considering the performance of our sales was impacted by shelves that were left empty for several weeks. Some stores simply decided to replace our empty spaces with other products, permanently.

Ironically, at the same time, we learned that we made the Profit500 rankings and we announced to the media significant investments in our facilities. We were overcoming a huge ordeal along with an hour of glory… a paradox indeed! In order to reach out to our customers and explain to them what had happened, we finally had enough perspective a year later to talk about it in the media and explain our setbacks. Following the article in La Presse, we got many messages of encouragement. Several customers confirmed that they had stopped buying our products, but that they were reassured to learn what had happened, and most importantly, they said that they would encourage us again.

In addition, at the time of this disaster, we were already implementing extremely demanding quality standards in our operations: We are now HACCP and GFSI (SQF) certified. But nothing can really protect a manufacturer from a dishonest supplier…

The happy ending? We were able to transform all of the quarantined products and some of the recall products into cattle feed (so not all a total waste) …. Let’s hope they did not notice the rancid taste And, of course, I ended up giving birth to a beautiful little boy, with some peace of mind…yes, some.

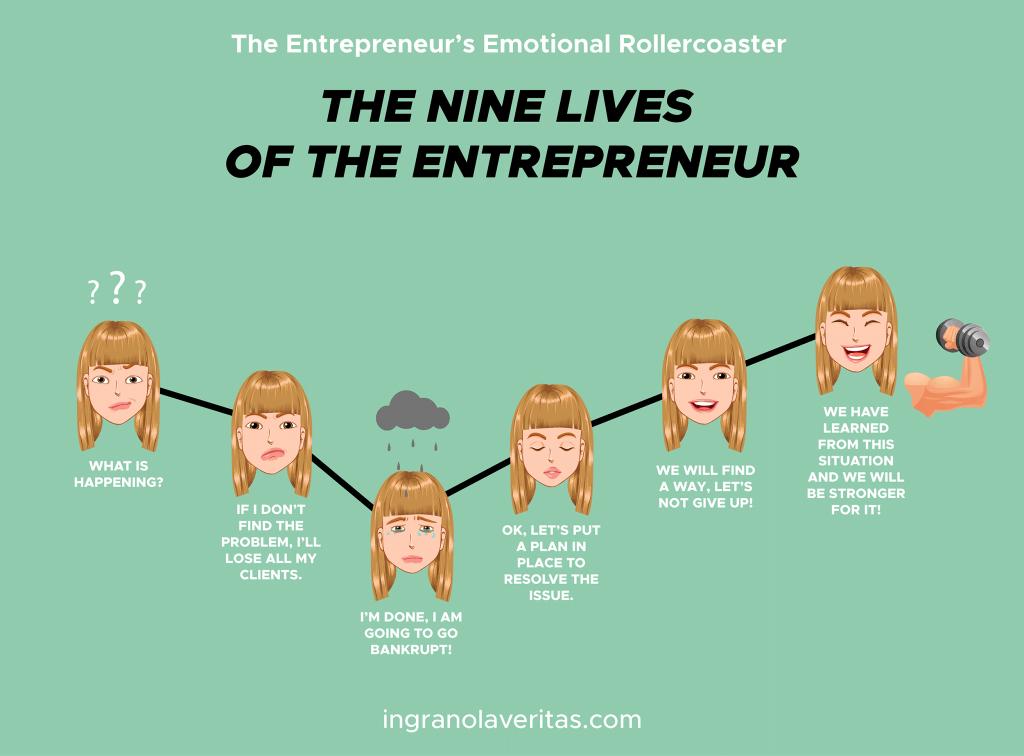

- Lesson n°1 Trusting your instinct: Even though I was told our situation was not covered by our insurance, I was not convinced, and my research helped me realize I was right;

- Lesson n°2 Making the right decision even when it’s not easy: Even though I did not know if I was going to get insurance coverage, I started a voluntary recall process because I knew it was the right decision to make, even if it was the most difficult to assume;

- Lesson n°3 Communicating with transparency: We communicated our situation clearly to our customers, partners and business associates throughout the process;

- Lesson n°4 Always keep calm in front of your employees: You need to be convinced that you will be able to get through the problem. If not, how can you convince your employees to deploy the necessary efforts to fix the situation?